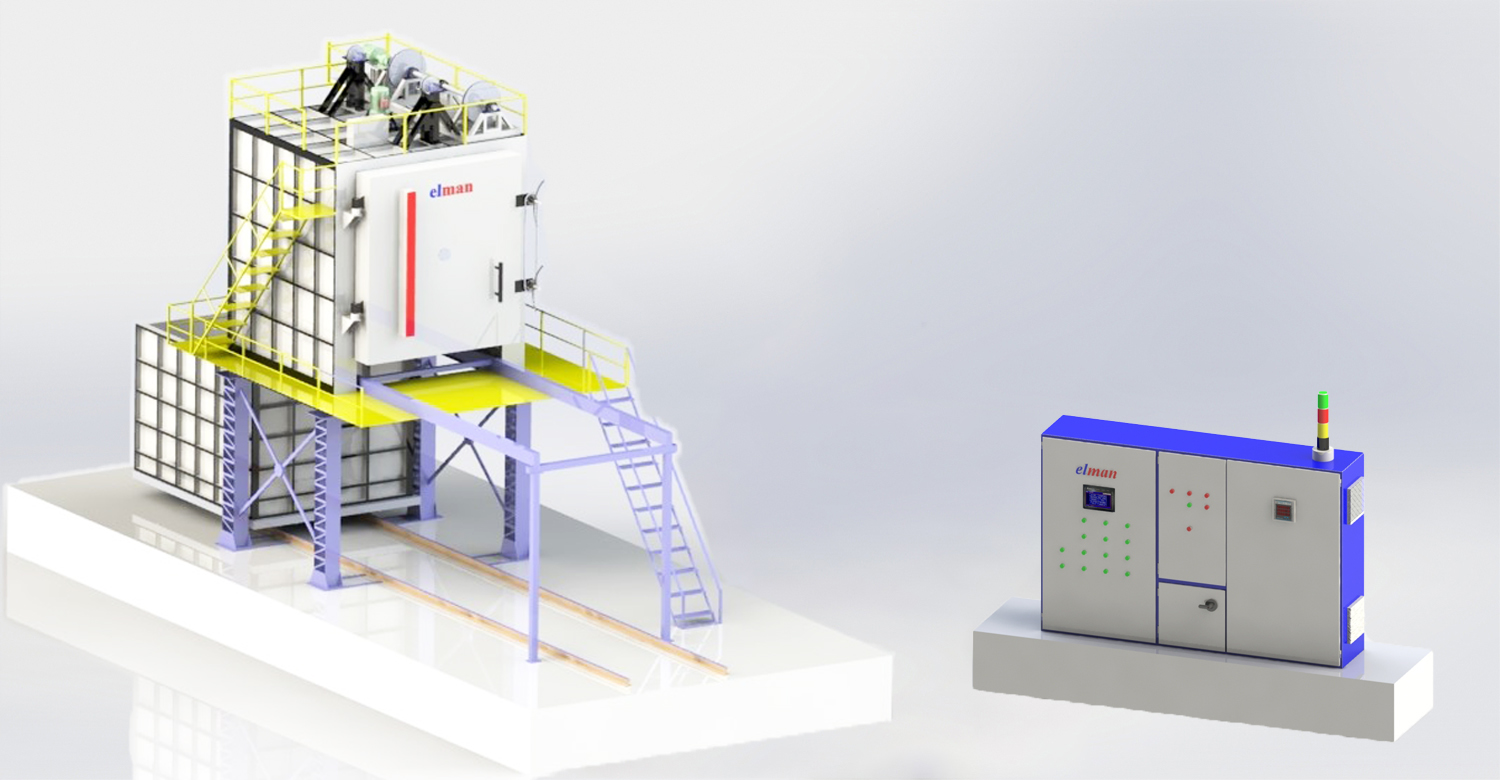

Drop Bottom Quenching/Water tank movable furnace

“ELMAN HAS BEEN DESIGNING, ENGINEERING AND MANUFACTURING INDUSTRIAL FURNACE AND HEAT TREATMENT EQUIPMENT FOR 15 YEARS”

www.elmanfurnace.com

Drop Bottom Quenching/Water Tank Movable Furnace by elman

Drop bottom quenching is a Worldwide the largest aircraft and transportation alloy components are heat treated by elman Drop Bottom quenching with water tank movable Solutionizing furnaces.

Drop bottom furnaces are typically used when very fast water quench times are required. The furnaces are designed to meet all requirements of Aerospace Material Specifications (AMS) AMS 2750E and AMS 2770N, NADCAP, RPS-953 and Boeing Aircraft (BAC) specifications. These furnaces are also used for solutionizing, ageing of structural parts, and in forging industries of aluminium alloys.

Elman has manufactured and installed drop bottom furnaces since 2006, with smallest load dimension of 3 ft up to the largest exceeding 65 ft. Our drop bottom with water tank movable furnaces are used for components as small as aircraft fasteners, all the way up to 65 ft wing extrusions. We have built drop bottoms for up to 20 ft diameter forged rings for rockets, large turbine inlet cones, and 30,000 pound loads for aircraft forgings.

For rapid and uniform convective heating our fan and duct air champer configurations is guarantee close temperature uniformity throughout the load chamber and parts. Computational Fluid Dynamic modeling predicts reliable machinery performance and allows elman and our customers to optimize part density and load rack configuration to increase machinery through-put.

Part marking and data acquisition can allow PLC/SCADA interface with your ERP software to assure bottom line predictability and part tracking documentation.The quenching trolly movement is faster than other furnace.

Specification

| Title | Description |

|---|---|

| Temperature range | Up to 700° C (for aluminium alloys) |

| Chamber design | Rectangular |

| Insulation | Ceramic Fibre Blanket + Brick/Ceramic Fibre Module & Board |

| Heating Media Options | Electric/Gas Fired/Oil Fired |

| Heating Element | Nichrome 80/20 / Special Alloy Resistance Heating Wire / A1-Kanthal |

| Furnace classification | Class 2/ Class 3 |

| Instrumentation option | Thyristor, Programmable Temperature Controller, Temperature Recorder, PLC, SCADA, HMI |

Related products

Interested to Know further?

Click on get quotes button below

- Equipment adopted to material norms AMS2770, 2771, 2772.

- Extremely tight temperature uniformity resulting by proven airflow innovation.

- Rapid load immersion time as short as 5 seconds.

- AMS2770 compliant quench transfer times.

- Low utilities consumption.

- SCADA with functionality enabling NADCAP certification.

- Specialized auxiliary equipment such as ammonium fluoride feeders, sulfur feeders, CO2 or N2 atmosphere systems, Argon fire extinguishing system, etc.

- Possibility of use water-polymer cooling tanks with refract to meters, Ph sensor and conductivity indicator.

- Software supporting TUS and SAT.

- Custom designed internal arrangement slots depending of the load configuration.

- Perfect solution for Aluminum and Magnesium alloys heat treatment.

- Aerospace

- Agriculture

- Automotive

- Forging

- Aluminum Casting

- Foundry

- Military

- Mining

- Recreational Vehicles

- PDC Heat Treatment

- Reverse airflow direction (Top to Bottom or Bottom to Top).

- Applicable for sheet, castings, tubes and extrusion.

- Custom designed fan assemblies.

- Movable or stationary water quench tanks.

- Different designs of water agitation units.

- Heating and cooling of the bath.

- Certified thermocouple modules for AMS requirements as well as recorder connected to SCADA.

- External recorder upon Customer’s request.

- Furnace designed according to newest AMS 2750F standard, innovative construction dedicated for furnaces class 2.

Why choose elman?

- Our furnaces are known for their accuracy, durability, reliability, high performance for a long period of time and easy and quick maintenance.

- For rapid quenching and uniform convective heating, our fan and duct configurations guarantee close temperature uniformity throughout the load chamber and parts.

- The quench delay as per AMS 2770N and AMS 2750E. Call us and see why aerospace, defence & casting companies bring their most stringent application requirements to elman for procuring drop bottom Quenching furnaces.

- Instrumentation options Thyristor, Programmable Temperature Controller, Temperature Recorder, PLC, SCADA, HMI.